Flow Meter Calibration and Repairs

Using a high precision Master Meter or Prover Tank the meters be calibrated to a maximum error of + 0.05% and a period of six months for re-calibration. Dynamic SLIP TEST on the meters enables us to predict the mechanical state of meter and permits useful recommendation. When the meter is out of calibration, repair is carried out (with client’s consent) and recalibrated.

Prover Tank Calibration

We undertake calibration of Prover Tank of all sizes using the Automatic Over flow pipe pipette gravy metrically calibrated to within 0.002% and traceable to international standards. We certify the Prover Tanks at 0.02%accuracy.

Shore Tank Calibration (Vertical, Horizontal

Barges and Ships)

The necessity of accurate tank calibration becomes particular evident where tanks are used for Stock

Control or Custody Transfer Measurements. We undertake calibration of Vertical Storage Tanks using Strapping Method in accordance with API 2551 Bottom volumes for Vertical Tanks can be determined by liquid fill or physical floor survey as requested. Horizontal Tanks, Ship and Barge Tanks can be determined by liquid fill or physical floor survey as requested. Horizontal Tanks, Ship and Barge Tanks are calibrated by Physical Strapping in accordance with API 2551 and 2553respectively.

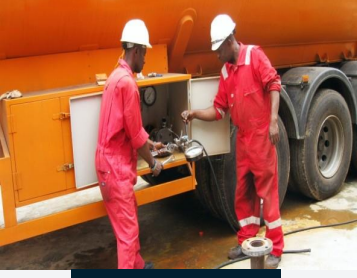

Road Truck Calibration.

We undertake calibration of Road Trucks of Petroleum product in the clients’ premises with our high precision Master or at oil Installation if required using the gantry Meters. The calibration can also be done within our premises (flowLab)

Surface and Underground Tank Calibration

These are calibrated by liquid fill method, the most accurate method of calibration using our high precision Master Meters. The liquid fill method in determining incremental volume of the tank takes into account the tilt of the tank underground.

Dispensing Pump Calibration

We undertake calibration of petroleum product dispensing pumps using our standard measures traceable to international standards for purpose of precise control of product quantities.

PROVER LOOP CALIBRATION

The foundation of accurate measurement is the confidence of the Prover Loop base volume accuracy. To achieve and maintain accurate results with Flow Meters, it is necessary to have a Measurement Standard against which to check them at frequent regular intervals.

If the base volume, which should be calibrated annually, is inaccurate, all subsequent meter factors would lack integrity and cause severe oil losses. In the crude oil terminals where the Measurement Standard is usually the Prover LOOP, it becomes very important and necessary to have them calibrated regularly. We calibrate and certify Prover Loop base volume to 0.02% accuracy. Our staffs have tremendous experience internationally in Prover Loop calibration using the Master Method.

- LPG Vessel Calibration

Starbest also undergo the calibration of LPG vessels and tank within

our customer’s premises to ascertain the quality and quantity of the vessels